Equipment

Equipment and Capabilities

Our equipment and capabilities include:

- Full machine shop including CNC milling machines, Haas TL-1 CNC lathe, Hardinge HLV-H precision toolroom lathes, drill press, and a wide array of fixtures and tooling to support precision machining of parts from plastics and metals

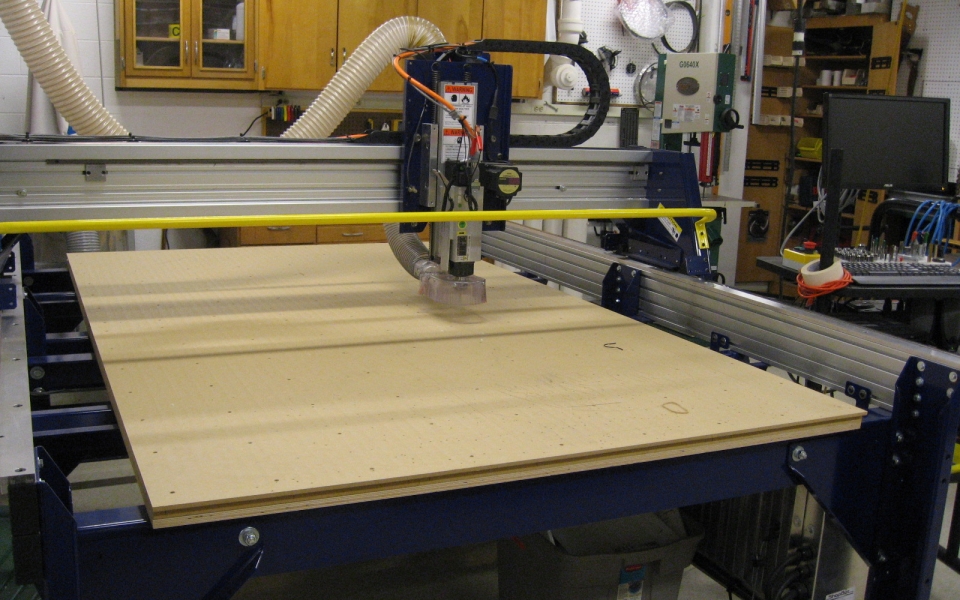

- ShopBot PRS Alpha 96-60 CNC Router Table for rapid and repeatable 2D, 2.5D, and 3D cutting of plastic and wood parts from large sheet stock

- Ultimaker 3, Lulzbot TAZ, and Stratasys uPrint SE Plus – 3D printers for rapid prototyping

- Metal cutting and welding capabilities including oxy-acetylene, plasma, MIG, and TIG

- Grinding, deburring, and polishing equipment and supplies

- Sheet metal working equipment including 52” shear, notcher, punches, slip roll, and magnetic bending brake.

- Basic electronics bench for instrument troubleshooting, circuit prototyping, and small scale electronics assembly.

- 3D Design Computer Workstation for design of components and assemblies with integral CAM capability for translation to CNC machining files.

- A variety of power and hand tools for working plastics, wood, and other non-metallic stock. These include table saw, miter saw, bandsaw, scrollsaw, drill press, planer, routers, sanders, drills, and their associated tooling.